Features

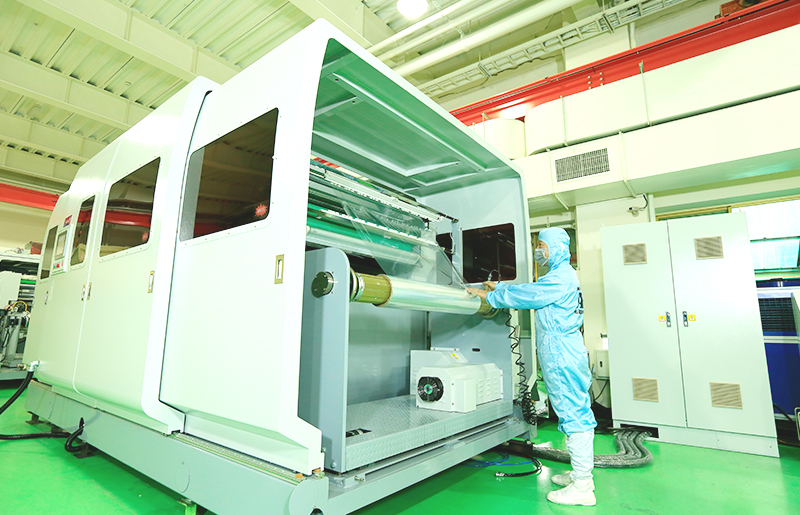

- The customized design and the modular mechanism allow the multi-purpose process to function.

- The servo system is used for the entire machine for higher accuracy.

- The photo eye automatically detects overflow of glue with auto tension control and auto edge alignment.

- We have developed the first clean sliding door for the machine guard in the world. It allows higher cleanliness for materials to improve yield.

- The quick plate change design can save you a lot of time for small-scale production of samples or volume production.

- Cleanliness class 1000

Functions

They can produce a variety of optical and smart films, luminous coatings, hardened protective coatings, and solar cells for exterior and interior trims in the photoelectric Industry.

Equipment Sold

UV forming machines、2-sided UV forming machines、Hybrid coating and forming machines、Alignment-type forming machines

| Coating width | 2100mm/1800mm/1400mm/600mm |

|---|---|

| Coating thickness | 2-150μm with an error value of ±1μm. The coating thickness and error value vary depending on the glue CPS and material characteristics. |

| Machine speed | 1-30 m/min which will be adjusted based on the light intensity and coating thickness. |

- Servo drive + PLC programming control

- HMI control system:

- The full-color touch monitor is used to display and record the operation status.

- Set several process parameters based on the production conditions.

- An abnormal alarm is issued automatically once any abnormal machine operations occur or any abnormal component is detected.

- Display abnormal status, and record abnormal causes as well as how to solve them

- Laminating mechanism:

1-side and 2-side lamination

- UV lamps:

Microwave lamps, electrode lamps, and LED lamps.

Optical film type

Back light modules (BEF brightness enhancement films, TAC polarizing films, diffuser films), Microlens hybrid optical films, micro structure films, electronic rear projection screens, flexible print circuit boards, metal mesh, light guide plate, prism films, and anti-oxidizing films.

Smart film type

3D lenticular lens, HC films, anti-blue light protectors, brushed films, privacy films, OCA, decoration films, carbon fiber, release films, aluminum plastic films, reflective films, AG films, AS films, and AF films.