Features

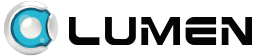

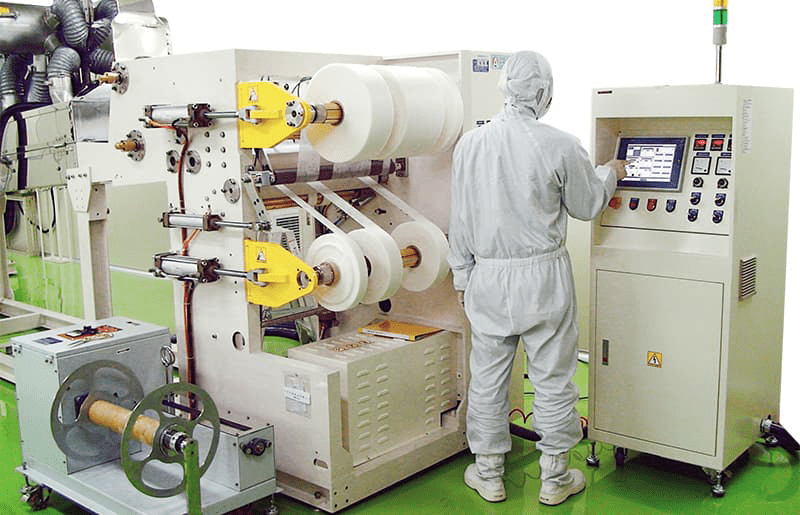

- The modular mechanism provides coating, laminating and slitting functions.

- The dressing thickness can be adjusted and they are suitable for several types of slot die and adhesives.

- The servo system is used for the entire machine for higher accuracy.

- The photo eye automatically detects overflow of glue with auto tension control and auto edge alignment.

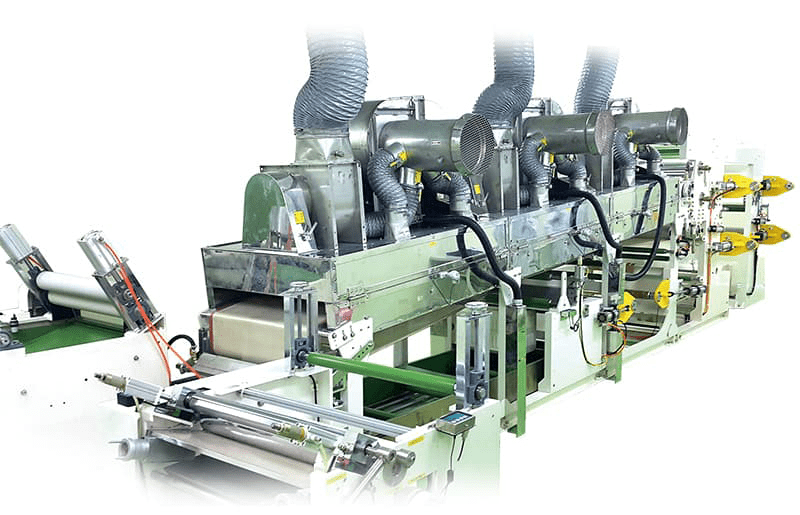

- The oven accurately provides parallel hot air for the even air flow and temperature.

Functions

Medicine coating, water-based glue coating, transfer coating, etc.

- Specification

- Mechanism

- Product Applications

| Coating dimension | 8600mm x 900mm x 2270mm |

|---|---|

| Coating thickness | Depending on the dressing |

| Machine speed | 10M/min which can be adjusted based on the material thickness |

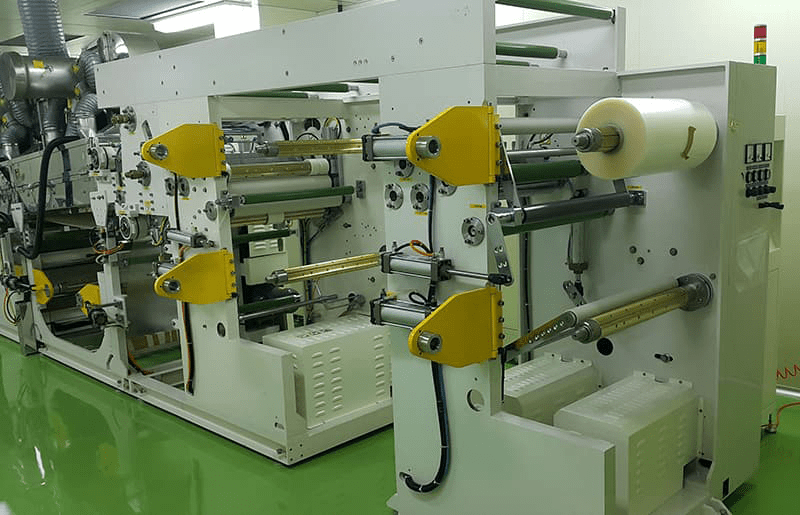

| Slitting knife | 12 pcs/knife holder + pneumatic lifting mechanism |

| Slitting precision | Within 0.10mm |

| Slitting thickness | 0.06mm-0.36mm |

- Servo drive + PLC programming control

- HMI control system:

- The full-color touch monitor is used to display and record the operation status.

- Set several process parameters based on the production conditions.

- An abnormal alarm is issued automatically once any abnormal machine operations occur or any abnormal component is detected.

- Display abnormal status, and record abnormal causes as well as how to solve them

- Oven:

Types/ Vertical type, clamshell type, and open side type

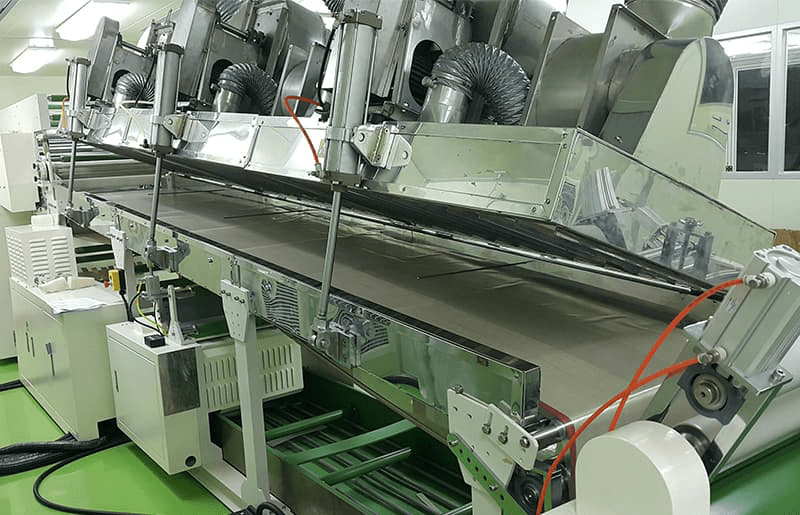

Drive/ air floating, roller drive - Laminating mechanism:

Wet and dry lamination

1-side and 2-side lamination

Medical type

Artificial skins, transdermal patches, various medicine coatings, face masks, breathable tape, and medical tapes.

Download

Download